If you want to know what print quality to expect if WATERPROOF PRINT is marked, you are in the right place.

During the Second World War, as well as now, large printing machines are used to print packaging materials. Nowadays, everyone is attracted by the possibility to print replicas of packaging on a color laser printer or a standard inkjet printer. In short, we will discuss the advantages and disadvantages of printers for the production of replicas.

Laser printer

Advantages

+ Cheap printing with black printing

+ Waterproof

+ Glossy print (if required)

+ Less maintenance (if you print once in a while)

Disadvantages

- Not suitable for various types of paper (the color does not stick to the paper)

- When the paper is folded, the color falls off

- Glossy print (not suitable for some products)

- Graphics must be thoroughly cleaned (preferably recreated)

Standard inkjet printer

Advantages

+ Prints on most materials

+ Color holds even when folded

+ You can find a cheap printer with cheap color (full color)

+ Matte print (which most closely resembles the war press)

+ It is not necessary to have completely clean graphics (fine inaccuracies will be lost)

Disadvantages

- Consumes ink when cleaning

- Color is not waterproof (color will smear)

Which printer is better for printing war copies?

Until recently, I used both variants:

Laser printer - black printing on paper on which the color retains and will not fold (most often self-adhesive labels)

Standard inkjet printer - for printing all other packaging that I know I will fold or they are different types of paper (recycled, thin, glossy, matte)

This means that products printed without WATERPROOF PRINT mark are printed on a standard inkjet printer and are ideal to use when it is not raining. But since the products do not avoid water, I gradually exchange the sold-out products for products with waterproof printing.

This means that if you see WATERPROOF PRINT symbol, it means that the print will last in direct contact with water for at least 2 minutes.

So these products meet the requirement of printing on an inkjet printer (which replaces large printing machines) and at the same time are waterproof. Because they did not have laser printers during World War II, and as mentioned above, it is difficult or impossible to print on some surfaces with a laser printer.

What does testing look like?

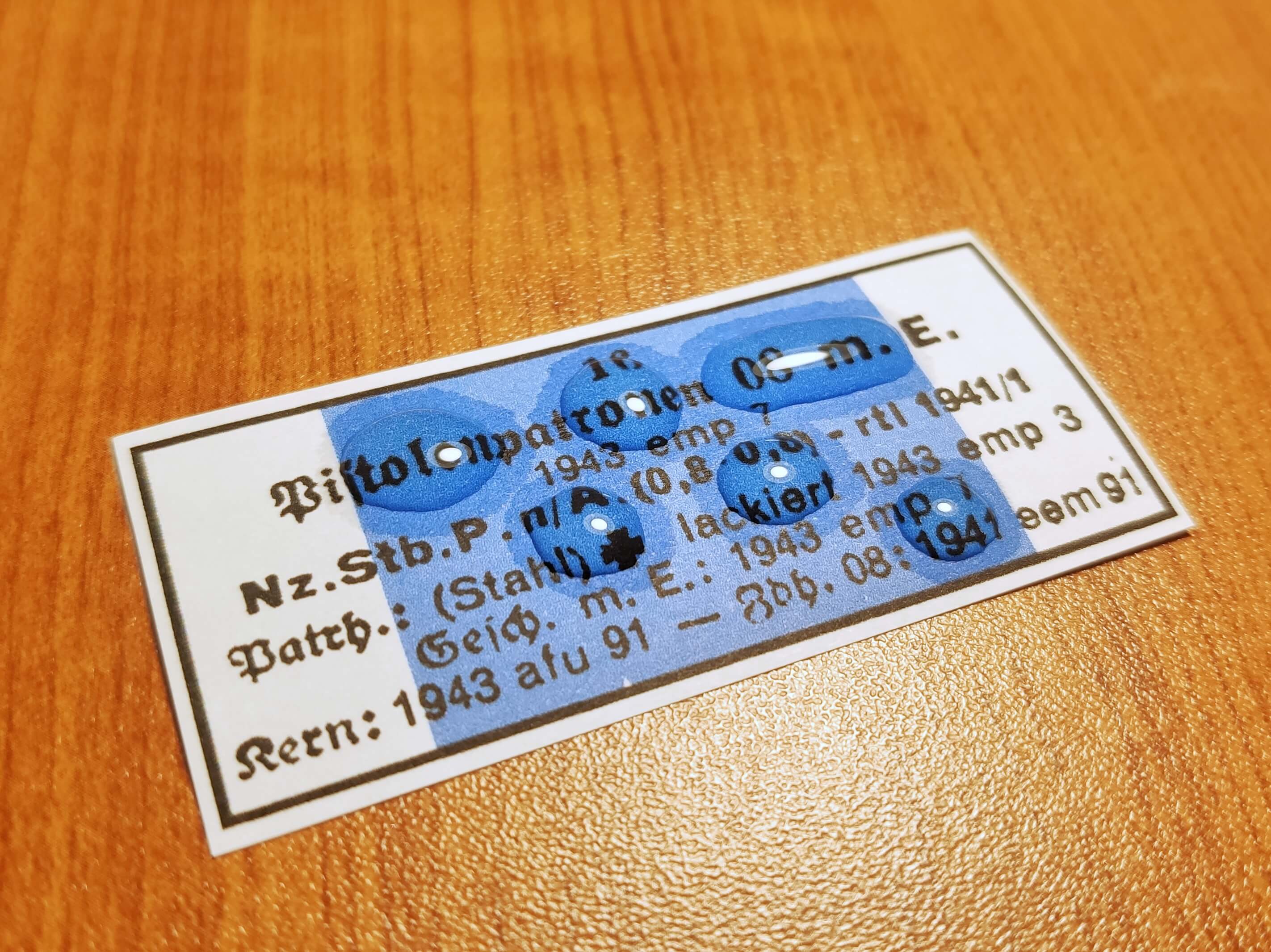

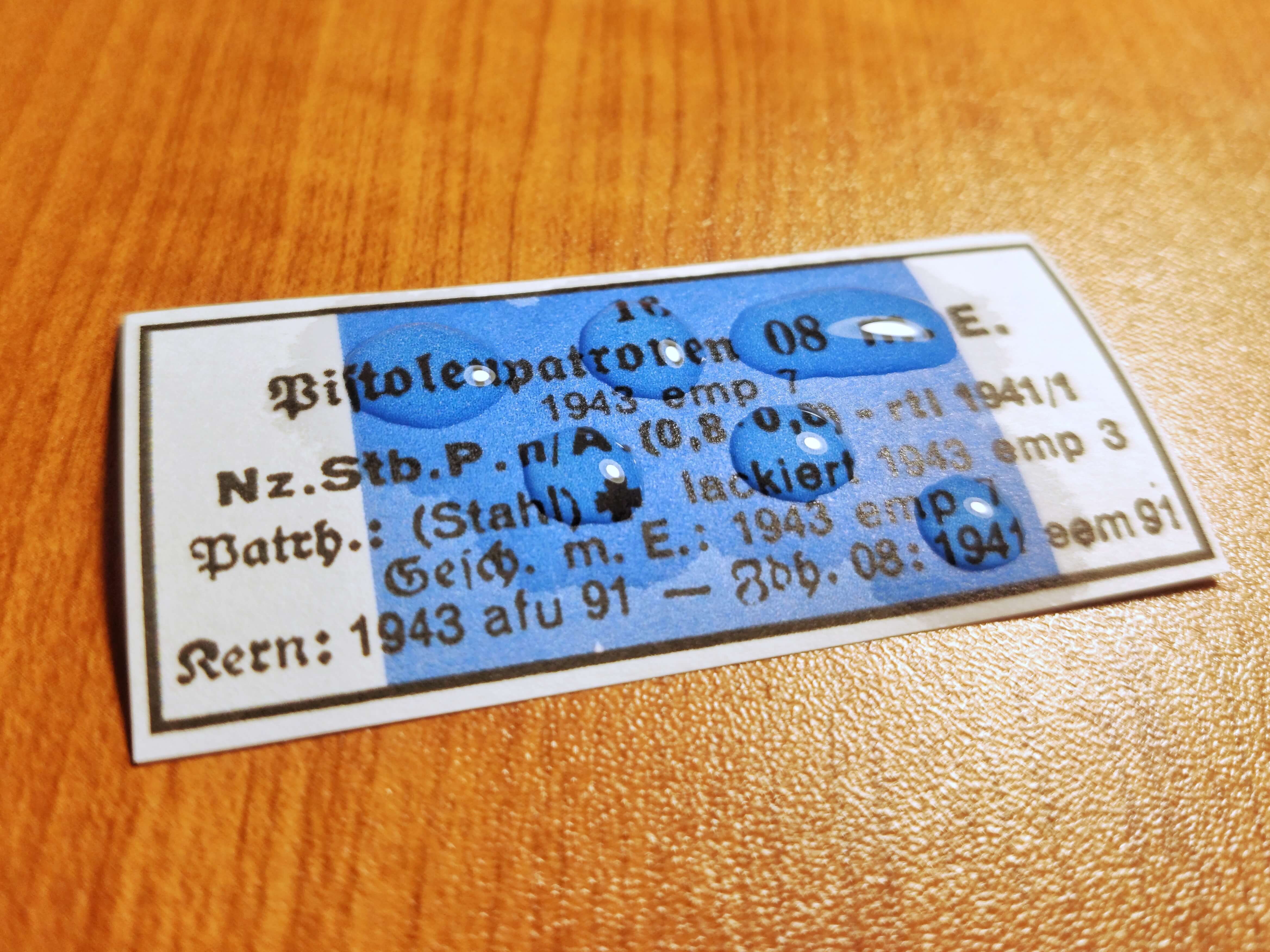

1. Application of water drops

1. Application of water drops

2. Waiting 2 minutes

2. Waiting 2 minutes

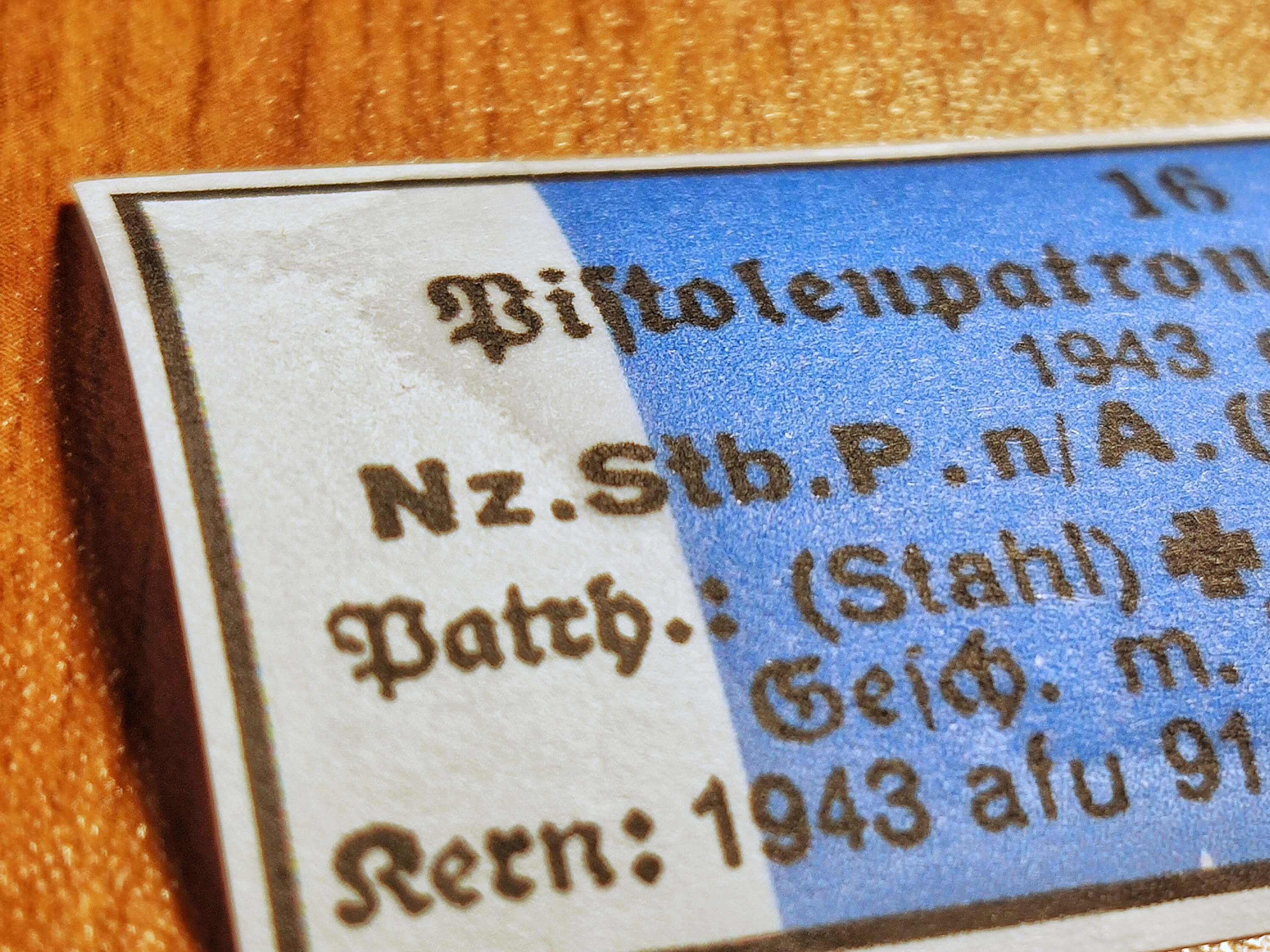

3. Detail after removing water drops

3. Detail after removing water drops